OEM/ODM Supplier Crystal Glass Tank - CBD oil Distiller Short Path Molecular Distillation Wiped Film Evaporator – Sanjing

OEM/ODM Supplier Crystal Glass Tank - CBD oil Distiller Short Path Molecular Distillation Wiped Film Evaporator – Sanjing Detail:

Quick Details

Molecular distillation is a distillation method operated under high vacuum, where the average free path of the vapor molecules is greater than the distance between the evaporating surface and the condensing surface.Thus, the liquid mixture can be separated by the difference of evaporation rate of each component in the feed liquid. At a given temperature, the lower the pressure, the greater the average free path of the gas molecules. When the pressure in the evaporation space is very low (10-2 ~ 10-4 mmHg) and the condensation surface is close to the evaporation surface, and the vertical distance between them is less than the average free path of the gas molecules, the vapor molecules vaporized from the evaporation surface can directly reach the condensation surface without colliding with other molecules and condense.

| Effective evaporation are | 0.15 |

| Key Selling Points | Easy to Operate |

| Rotating Speed | 600 |

| Machine type | Short Path Distiller |

| Power | 250 |

| Material | 3.3 borosilicate glass |

| Process | Vacuum Distillation |

| After Warranty Service | Online support |

Product Description

● Product Attribute

| Model | SPD-80 | SPD-100 | SPD-150 | SPD-200 |

| Feed Rate(kg/hr) | 4 | 6 | 10 | 15 |

| Effective evaporation area(m²) | 0.1 | 0.15 | 0.25 | 0.35 |

| Motor Power(w) | 120 | 120 | 120 | 200 |

| Maximum Speed(rpm) | 500 | 500 | 500 | 500 |

| Barrel Diameter(mm) | 80 | 100 | 150 | 200 |

| Feeding Funel Volume(l) | 1 | 1.5 | 2 | 5 |

| Dimension (mm) | 2120*1740*628 | 2120*1740*628 | 2270*1940*628 | 2420*2040*628 |

| Inernal Condenser Area(m) | 0.2 | 0.3 | 0.4 | 0.5 |

| Distillate Receiving Vessel Volume(l) | 1 | 2 | 5 | 10 |

| Residue Receiving Vessel Volume(l) | 1 | 2 | 5 | 10 |

| Wiper | PTFE scraper | PTFE scraper | PTFE scraper | PTFE scraper |

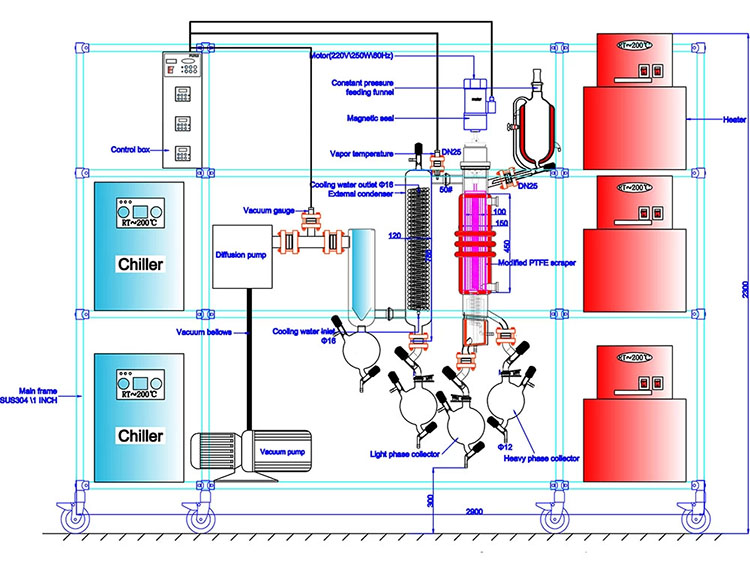

● Product features

High evaporation efficiency can reduce retention time with minimal time delay.

Short path distillation is made of 3.3 high borosilicate glass and PTFE, which has excellent corrosion resistance.

Main body of short path distillation is made of 3.3 high borosilicate glass , allowing the whole process to be observed very clearly.

High precision distillation barrel allows the liquid to form a complete and unifiedthin film on the heated surface. The smooth inner surface can avoid stick and scalin.

Frequency conversion deceleration motor with selfcooling fan, long time continuous working.

Magnetic force transmission can make film forming system separated from motor, the top sealing of distillation barrel have no drive rod pass through.The whole system performs a completed sealing. The minimumvacuum pressure is up to0.1Pa.

Highest temperature of the system can reach 230℃/300℃, accurate temperature control can be realized.

Scraper model and self-cleaning roller model film forming system are available.

FAQ

1. Are you trading company or manufacturer?

We are professional manufacturer of lab equipment and we have our own factory.

2. How long is your delivery time ?

Generally it is within 3 working days after receiving the payment if the goods are in stock. Or it is 5-10 working days if the goods are out of stock.

3. Do you provide samples? ls it free?

Yes, we could offer the sample. Considering the high value of our products,the sample is not free, but we’ll give you our best price including shipping cost.

4. What is your terms of payment?

100% Payment before shipment or as negotiated terms with clients. For protecting clients’ payment security, Trade Assurance Order is highly recommended.

Product detail pictures:

Related Product Guide:

It really is our obligation to satisfy your requirements and efficiently serve you. Your fulfillment is our greatest reward. We're hunting forward to your check out for joint development for OEM/ODM Supplier Crystal Glass Tank - CBD oil Distiller Short Path Molecular Distillation Wiped Film Evaporator – Sanjing , The product will supply to all over the world, such as: Hyderabad, Amman, Turkey, Corporate goal: Customers' satisfaction is our goal, and sincerely hope to establish long-terms stable cooperative relations with customers to jointly develop the market. Building brilliant tomorrow together!Our company regards "reasonable prices, efficient production time and good after-sales service" as our tenet. We hope to cooperate with more customers for mutual development and benefits. We welcome potential buyers to contact us.

The company can keep up with the changes in this industry market, product updates fast and the price is cheap, this is our second cooperation, it's good.