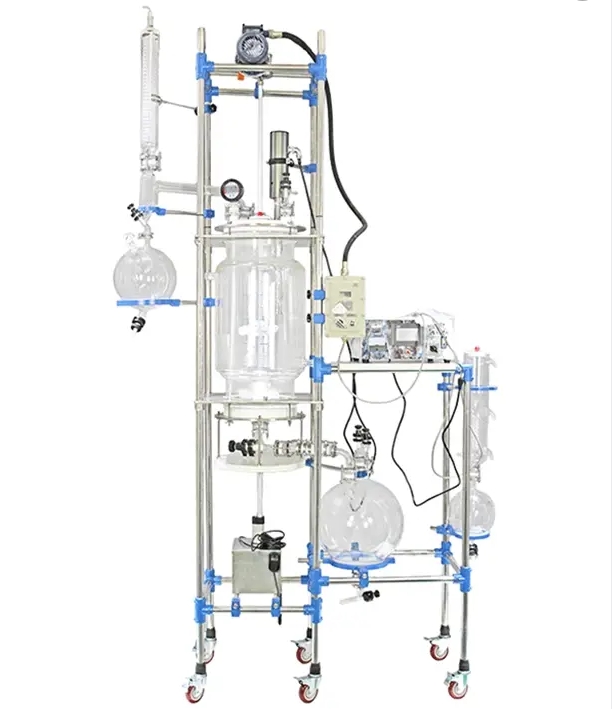

Sanjing Chemglass is revolutionizing the chemical industry with its state-of-the-art Chemical Glass Reactor equipped with an Ultrasonic Wave System. This advanced reactor is designed to meet the diverse needs of clients, offering customizable stages and explosion-proof electrical components for safe and efficient chemical processing.

Product Overview

The reactor operates with an automatic grade and is primarily used for fermentation extraction. Its ease of operation is a key selling point, making complex processes accessible to a broader range of operators.

Material and Design

Constructed from high borosilicate glass 3.3, the reactor boasts exceptional durability and resistance to thermal shock. It operates effectively within a temperature range of -100 to 250 degrees Celsius, utilizing thermal oil heating for precise temperature control.

After-Sales Support

Sanjing Chemglass ensures peace of mind with comprehensive after-warranty services, including video technical support, online assistance, and readily available spare parts.

Customization and Features

• Parts Customization: Tailored to specific requirements, the reactor can include an independent vapor riser, enhancing the efficiency of reflux, distillation, and water separation processes.

• Stirring Paddle: A variety of stirring paddles can be chosen to achieve optimal mixing effects, with the option to install a four-raised apron for improved fluid flow.

• Reactor Cover: The multi-necked cover, made from the same high-quality glass, can be customized in terms of neck numbers and sizes.

• Vessel: The double glass jacketed vessel ensures excellent visibility and effect, with the option to connect to a vacuum pump for ultralow temperature reactions.

Conclusion

Sanjing Chemglass’s Chemical Glass Reactor with Ultrasonic Wave System is a testament to the company’s commitment to innovation and quality. With its customizable features, robust construction, and user-friendly design, it stands as an essential tool for any chemical processing facility seeking to enhance its capabilities and safety measures.

If you are interested, please contact us:

Email: joyce@sanjingchemglass.com

WhatsApp: +86 138 14379692

Post time: May-29-2024