Selecting the appropriate laboratory glass reactors is crucial for the success of your experiments and processes. At Nantong Sanjing Chemglass Co., Ltd., we specialize in the research and production of high-quality glass instruments, including glass reactors, that cater to various laboratory needs. In this blog, we will discuss the main types of laboratory glass reactors, the criteria for selection, and their application scenarios to help you make the best choice for your laboratory.

Understanding the Types of Laboratory Glass Reactors

Laboratory glass reactors come in various designs, each tailored for specific applications. Here are some of the most common types:

Single-Layer Glass Reactors: These are the simplest form of laboratory glass reactors, ideal for basic chemical reactions. They are typically used for small-scale experiments where temperature control is not critical.

Double-Layer Glass Reactors: Featuring an outer layer that allows for heating or cooling, double-layer reactors are perfect for reactions requiring precise temperature control. The space between the layers can be filled with water or oil, making them suitable for a variety of applications.

Multi-Layer Glass Reactors: These reactors offer even more versatility, allowing for simultaneous reactions at different temperatures or conditions. They are ideal for complex processes that require multiple stages.

Vacuum Glass Reactors: Designed for reactions that need to be conducted under vacuum conditions, these reactors minimize the risk of oxidation and contamination. They are commonly used in the pharmaceutical and chemical industries.

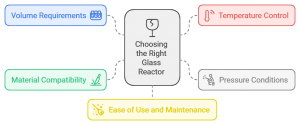

Criteria for Choosing the Right Glass Reactor

When selecting laboratory glass reactors, consider the following factors:

Volume Requirements: Determine the scale of your experiments. Smaller reactors are suitable for preliminary studies, while larger ones are necessary for production-scale processes.

Temperature Control: Assess the temperature requirements of your reactions. If precise temperature control is essential, opt for double-layer or multi-layer reactors.

Pressure Conditions: If your experiments involve high pressures or vacuum conditions, ensure that the reactor is designed to withstand such environments.

Material Compatibility: Ensure that the glass reactor is made from high-quality borosilicate glass, which offers excellent chemical resistance and thermal stability.

Ease of Use and Maintenance: Choose a reactor that is user-friendly and easy to clean. This will save time and reduce the risk of contamination.

Application Scenarios for Laboratory Glass Reactors

Laboratory glass reactors are versatile tools used in various fields, including:

Chemical Synthesis: Ideal for conducting chemical reactions, these reactors allow for precise control over reaction conditions.

Pharmaceutical Development: In drug formulation and testing, laboratory glass reactors provide the necessary environment for synthesizing active pharmaceutical ingredients (APIs).

Material Science: Researchers use glass reactors to develop new materials, including polymers and nanomaterials, under controlled conditions.

Environmental Studies: These reactors are also employed in studies related to environmental chemistry, such as the degradation of pollutants.

Conclusion

Choosing the right laboratory glass reactors is essential for achieving optimal results in your experiments. At Nantong Sanjing Chemglass Co., Ltd., we offer a wide range of high-quality glass reactors designed to meet the diverse needs of laboratories. By considering the types, selection criteria, and application scenarios discussed in this blog, you can make an informed decision that enhances your research capabilities. Our commitment to quality and innovation ensures that you receive the best products to support your scientific endeavors. Let us help you elevate your laboratory experience with our state-of-the-art laboratory glass reactors.

Post time: Oct-29-2024