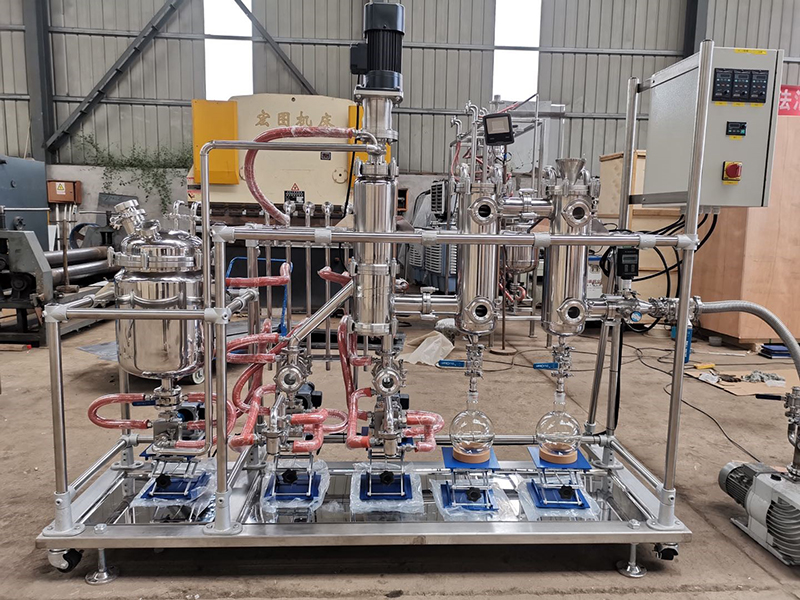

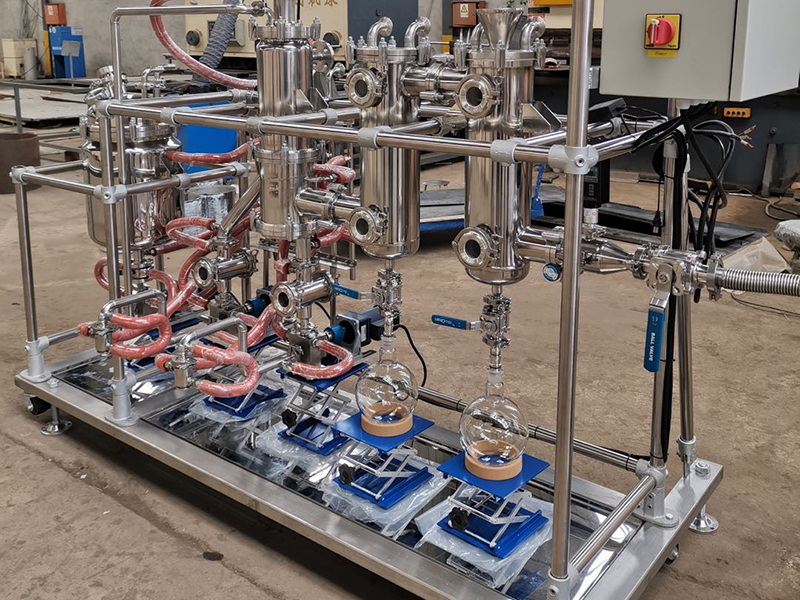

A wiped film evaporator is a type of distillation apparatus that uses a rotating wiper blade to spread a thin film of liquid over the inner surface of a heated cylindrical vessel. The wiper blades help to ensure an even distribution of heat and minimize fouling or buildup on the heating surfaces. As the liquid moves through the evaporator, it is rapidly vaporized and condensed into separate fractions based on their boiling points. This process can be used for purifying and separating various types of liquids, such as oils, chemicals, pharmaceuticals, and food products. Wiped film evaporators are often used in industrial settings due to their high efficiency and scalability for large-scale production.

The wiped film evaporator offers several advantages over other types of distillation equipment. Here are some of the advantages:

1. High Efficiency: The design of the wiped film evaporator allows for very high heat transfer rates, resulting in shorter processing times and higher throughput.

2. Minimal Product Degradation: Because the liquid is spread out into a thin film, it is exposed to less heat than if it were held in a pool or batch operation, leading to minimal product degradation.

3. Precise Control: With precise control over process parameters such as temperature and pressure, the wiped film evaporator can achieve excellent separation results with minimal loss of desired components.

4. Easy Cleaning and Maintenance: The cylindrical vessel design ensures easy cleaning and maintenance, reducing downtime for production runs.

5. Versatile Applications: Wiped film evaporators can be used for a wide range of applications including pharmaceuticals, chemicals, food products, oils and more.

The function of a wiped film evaporator is to separate compounds from a mixture by evaporation based on differences in their boiling points. By spreading out the liquid into a thin layer across heated surfaces within the apparatus , rapid evaporation occurs which leads to effective fractionation/separation between volatile components from non-volatile ones that remain behind. The vaporized component condenses at another location within the system where it can then be collected separately thereby allowing different compounds found in one solution/mixture being separated efficiently according to their differing volatilities. This makes wiped-film-evaporators ideal instruments especially when trying to extract highly purified substances or when concentrating solutions requiring removal/recovery of solvent without thermal damage.

Post time: Aug-22-2023