Newly Arrival 2l Rotary Evaporator - 50L Rotary Evaporator With Chiller And Vacuum Pump Used For Vacuum Distilltion And Ethanol Recovery – Sanjing

Newly Arrival 2l Rotary Evaporator - 50L Rotary Evaporator With Chiller And Vacuum Pump Used For Vacuum Distilltion And Ethanol Recovery – Sanjing Detail:

Quick Details

| Capacity | 2-5L |

| Key Selling Points | Automatic |

| Rotating Speed | 10-180Rpm |

| Type | Standard Type |

| Power Source | Electric |

| Glass Material | GG-17(3.3) Borosilicate Glass |

| Process | Rotary, Vacuum Distillation |

| After Warranty Service | Online support |

Product Description

● Product Attribute

| Product Modle | PR-2 | PR-5 |

| Evaporation Flask(L) | 2L/29# | 5L/50# |

| Receiving Flask(L) | 1L | 2L/3L |

| Evaporation Speed(H₂O)(L/H) | 1.2 | 2 |

| Receiving Flask(KW) | 1.5 | 2 |

| Motor Power(w) | 40 | 140 |

| Vacuum Degree(Mpa) | 0.098 | 0.098 |

| Rotation Speed(rpm) | 10-180 | 10-90 |

| Power(V) | 220 | 220 |

| Diamension(mm) | 55*35*75 | 55*35*110 |

● Product features

3.3 BOROSILICATE GLASS

-120°C~300°C Chemical temperature

VACUUM AND CONSTANT

ln quiescent state,vacuum rate of its inner space can reach

304 STAINLESS STEELT

Removable stainless steel frame

VACUUM DEGREE INSIDE THE REACTOR

Stirring hole of the lidwill be sealed by alloysteel mechanical sealing part

High evaporation and recovery rate, advanced frequency conversion and electronic speed control was applied to ensure stable operation of the motor.

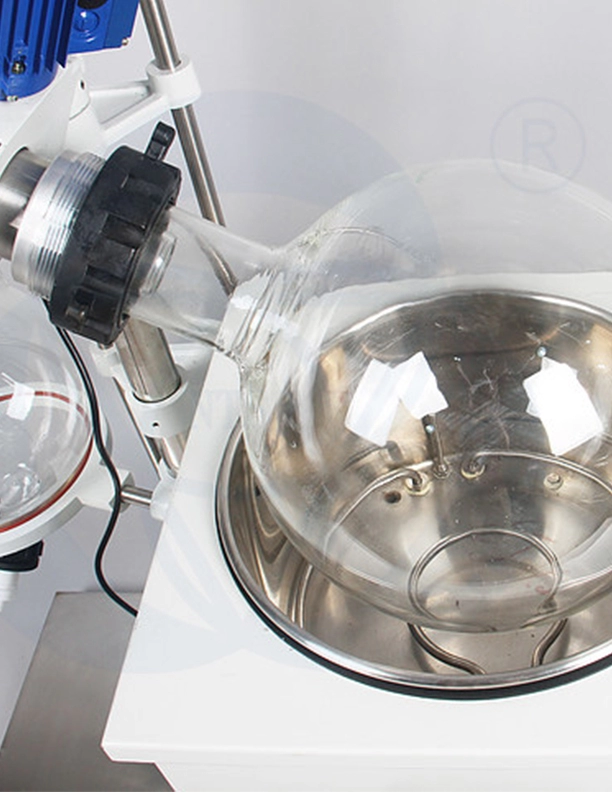

Bath pot can be easily lifted by electricity; and the collection flask can be immersed in an ice bath to reduce the second evaporation under the low boiling point.

Receiving flask connected to spherical neck can be easily assembled and perfectly sealed.

Long lasting seal under high temperature, to ensure the corrosion resistance and durability of the dynamic sealing system with good air-tightness.

Japanese Technology AC induction motor, variable speed, no brush, no spark, can work effectively for a long time.

Intelligent temperature control, can work with both water and oil bath, more widely used. Temperature fluctuation is only +0.2 ℃. Evaporation is more stable and material can not be washed easily.

The series modular design on the whole set makes it extensible and easy to install, and more convenient to maintain.

Explosion proof system can be applied to electrical parts according to user’s requirements.

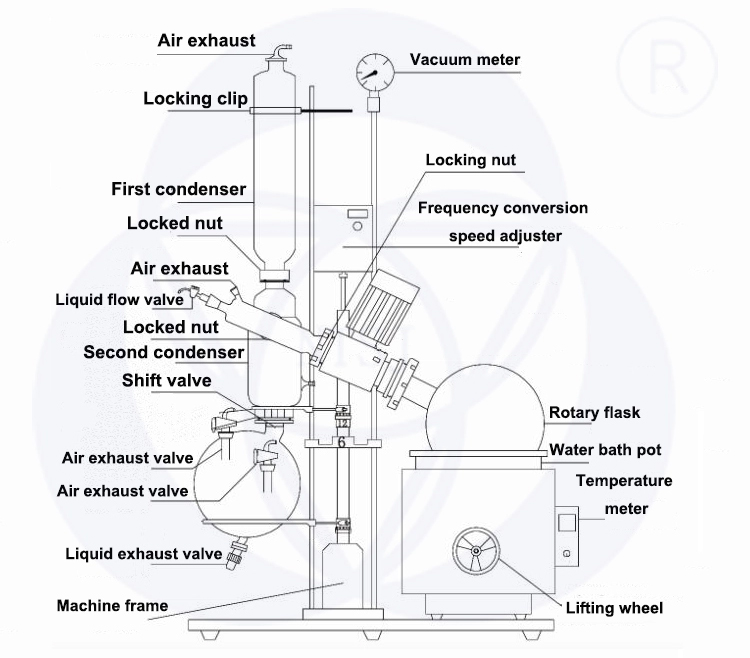

Detailed Explanationof Structure

Video

Details

High Efficiency Coil Condenser

Cochlear

Air Bottle

Receiving

Flask

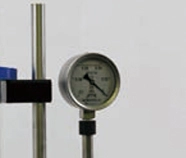

Shock Proof Vacuum Gauge

Frequency Conversion Control Box

New Type Of Ac Induction Motor

Rotary

Evaporator

Water And

Oil Bath

FAQ

1. Are you trading company or manufacturer?

We are professional manufacturer of lab equipment and we have our own factory.

2. How long is your delivery time ?

Generally it is within 3 working days after receiving the payment if the goods are in stock. Or it is 5-10 working days if the goods are out of stock.

3. Do you provide samples? ls it free?

Yes, we could offer the sample. Considering the high value of our products,the sample is not free, but we’ll give you our best price including shipping cost.

4. What is your terms of payment?

100% Payment before shipment or as negotiated terms with clients. For protecting clients’ payment security, Trade Assurance Order is highly recommended.

Product detail pictures:

Related Product Guide:

We believe that long time period partnership is a result of top of the range, value added services, rich expertise and personal contact for Newly Arrival 2l Rotary Evaporator - 50L Rotary Evaporator With Chiller And Vacuum Pump Used For Vacuum Distilltion And Ethanol Recovery – Sanjing , The product will supply to all over the world, such as: Spain, Mozambique, Bangladesh, Welcome to visit our company, factory and our showroom where displays various hair products that will meet your expectation. Meanwhile, it is convenient to visit our website, and our sales staff will try their best to provide you the best service. Please contact us if you need more information. Our aim is to help customers realize their goals. We are making great efforts to achieve this win-win situation.

The manufacturer gave us a big discount under the premise of ensuring the quality of products, thank you very much, we will select this company again.