Manufacturer of 5l Glass Reactor - Customized Electric Heating Industrial Jacketed Glass Enameled Reactor – Sanjing

Manufacturer of 5l Glass Reactor - Customized Electric Heating Industrial Jacketed Glass Enameled Reactor – Sanjing Detail:

Quick Details

| Automatic Grade | Automatic |

| Type | Reaction Kettle |

| Core Components | Engine, Motor, Pressure vessel |

| Glass Material | High Borosilicate Glass 3.3 |

| Working Temperatur | -100-250 |

| Heating Method | Thermal Oil Heating |

| After Warranty Service | Online support |

Product Description

● Product Attribute

| Product Modle | FPGR-50 | FPGR-80 | FPGR-100 | FPGR-150 | FPGR-200 |

| Volume(L) | 50 | 80 | 100 | 150 | 200 |

| Neck No.on Cover | 6 | 6 | 6 | 6 | 6 |

| External Diameter of Inner Vessel(mm) | 365 | 410 | 460 | 550 | 600 |

| External Diameter of Outer Vessel(mm) | 410 | 460 | 500 | 600 | 650 |

| Cover Diameter (mm) | 265 | 340 | 340 | 340 | 340 |

| Vessel Height(mm) | 850 | 950 | 950 | 980 | 1200 |

| Motor Power(W) | 180 | 370 | 370 | 750 | 750 |

| Vacuum Degree(Mpa) | 0.098 | 0.098 | 0.098 | 0.098 | 0.098 |

| Rotation Speed(rpm) | 50-600 | 50-600 | 50-600 | 50-600 | 50-600 |

| Torque(Nm) | 2.86 | 5.89 | 5.89 | 11.9 | 11.9 |

| Power(V) | 220 | 220 | 220 | 220 | 220 |

| Diamension(mm) | 700*300*2300 | 1000*700*2500 | 1000*700*2700 | 1200*900*3000 | 1200*900*3200 |

● Product features

1. The whole stainless steel frame structure (the connection part of the three-way and four-way exquisite connection) is compact and firm, and it’s easy to move.

2. VFD(variable-frequency drive) motor controller can realize high-medium-low-speed operation, which is accurate and operable. And fully explosion-proof system is feasible.

3. The kettle chamber and jacket are designed without dead angle, and the special solid feeding port on the cover is convenient for cleaning without disassembly.

4. The lower discharge part is easy to release concentrated liquid and residuum.

5. The heating (cooling) solution in the sandwich layer will be completely eliminated after the reaction.

3.3 BOROSILICATE GLASS

-120°C~300°C Chemical temperature

VACUUM AND CONSTANT

ln quiescent state,vacuum rate of its inner space can reach

304 STAINLESS STEELT

Removable stainless steel frame

VACUUM DEGREE INSIDE THE REACTOR

Stirring hole of the lidwill be sealed by alloysteel mechanical sealing part

Detailed Explanationof Structure

Details

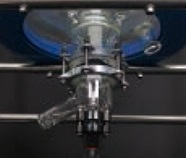

Vacuum Gauge

Condenser

Receiving Flask

Discharge Value

Lockable Casters

Control Box

Reactor Cover

Vessel

Parts Customization

● Products can be customized according to requirements

Independent vapor riser can be adopted as per client’s request, withthe vapor come into the condenser in downward direction, then liquidcan be refluxed from the liquid sealing flask under the condenser after condensing, therefore it avoids the second heating of menstruumcaused by traditional way that vapor and liquid flowing in samedirection, reflux, distillation, water separation etc can also be donewith better effec tsame as mass production process.

● Stirring paddle

Different types of stirring paddles(anchor, paddle, frame, impeller etc) can be selected.Fourraisedapron can be fired in the reactor as per client’s request, so that fluid flowcan be interfered henmixing to get to a more ideal mixing effect.

● Reactor cover

Multi-necked reactor cover is made of 3.3 borosilicate glass, number of necks and sizes can be custom made.

● Vessel

Double glass jacketed reactor who has perfect effectand good sight can be made according to customer’s requirements, whose jacket can be connected tovacuum pump to preserve the heat when makingultralow temperature reaction.

FAQ

1. Are you trading company or manufacturer?

We are professional manufacturer of lab equipment and we have our own factory.

2. How long is your delivery time ?

Generally it is within 3 working days after receiving the payment if the goods are in stock. Or it is 5-10 working days if the goods are out of stock.

3. Do you provide samples? ls it free?

Yes, we could offer the sample. Considering the high value of our products,the sample is not free, but we’ll give you our best price including shipping cost.

4. What is your terms of payment?

100% Payment before shipment or as negotiated terms with clients. For protecting clients’ payment security, Trade Assurance Order is highly recommended.

Product detail pictures:

Related Product Guide:

We know that we only thrive if we can easily guarantee our combined cost competiveness and high-quality advantageous at the same time for Manufacturer of 5l Glass Reactor - Customized Electric Heating Industrial Jacketed Glass Enameled Reactor – Sanjing , The product will supply to all over the world, such as: Bangkok, Russia, Cannes, Only for accomplishing the good-quality product to meet customer's demand, all of our products have been strictly inspected before shipment. We always think about the question on the side of the customers, because you win, we win!

On this website, product categories is clear and rich, I can find the product I want very quickly and easily, this is really very good!